Disruptions Dawn: Clustering Innovations

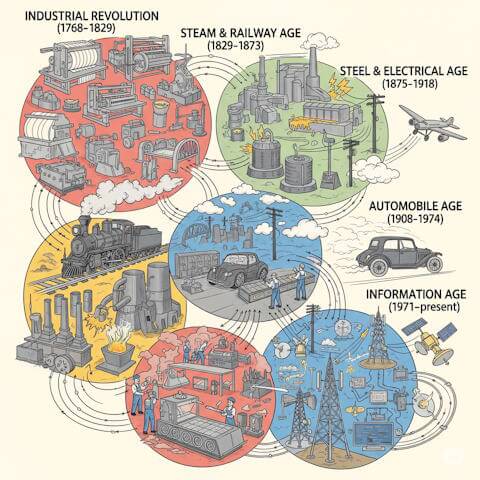

Innovation Clustering Across Five Technological Big Bang Events:

Innovation clustering represents humanity’s evolving mastery of technological coordination across five transformative technological cycles. This comprehensive analysis examines how societies progressed from organic emergence to sophisticated ecosystem orchestration between 1771 and the present day. Each cycle demonstrates increasing sophistication in coordinating complex technological systems while creating powerful network effects and competitive advantages.

Historical evidence reveals systematic patterns in how technological innovations converge to create transformative capabilities. These patterns transcend specific technologies and demonstrate fundamental principles of system coordination. Moreover, understanding these evolutionary trajectories provides crucial insights for managing contemporary technological development and preparing for future challenges.

Cycle 1: Industrial Revolution – The Foundation of Systematic Manufacturing

The Industrial Revolution established humanity’s first systematic approach to mechanized production coordination. Richard Arkwright’s 1771 Cromford Mill exemplifies this organic clustering pattern where water power, mechanical innovations, and skilled labor concentrated around geographical advantages. Subsequently, this convergence created replicable organizational models that transformed textile manufacturing globally.

Water frame spinning machines enabled continuous thread production with unprecedented consistency. Carding engines mechanized fiber preparation through automated combing processes. Power looms began mechanizing weaving operations to match increased thread production capacity. Furthermore, these core technologies achieved transformative power through integration within carefully designed physical and organizational systems.

Mill architecture represented revolutionary approaches to industrial organization through multi-story buildings optimized for power transmission and workflow efficiency. Water management systems converted natural flow into reliable mechanical power through dams, sluices, and engineered wheel systems. Additionally, gear-driven transmission distributed power throughout facilities with unprecedented efficiency and reliability.

The factory system itself departed fundamentally from traditional domestic production by concentrating workers, machines, and materials within integrated facilities. New approaches to labor organization, work scheduling, and quality control created human systems necessary for realizing mechanical potential. Consequently, these organizational innovations proved equally crucial as technological developments for enabling sustained industrial operation.

Technical standardization emerged organically from practical necessity as mill operators discovered optimal configurations through experimentation. Frame spindle dimensions became standardized within facilities to enable interchangeable parts and maintenance simplification. Gear ratios for water systems achieved optimization through empirical testing and gradual standardization across operations. Nevertheless, interoperability remained limited primarily to mechanical compatibility within individual mills rather than broader industrial networks.

Process standards developed around continuous operation requirements and quality control necessities. Standardized mill floor layouts emerged as operators learned to optimize power transmission and workflow patterns. These layouts became templates for replication across multiple facilities, representing early examples of systematic knowledge transfer. Moreover, work processes became standardized around mechanical system capabilities, establishing industrial time discipline foundations.

Network effects during this cycle operated primarily through geographical clustering and local supplier development. Mills created direct network effects by concentrating specialized workers, machines, and supporting services within regional clusters. Indirect effects emerged through supporting industries developing specialized capabilities for textile manufacturing. Furthermore, path dependence characteristics proved remarkably durable, with industrial regions maintaining specialization for decades after initial establishment.

Learning effects proved particularly important as operators developed tacit knowledge about machine operation, maintenance, and optimization techniques. This accumulated knowledge represented competitive advantages difficult to transfer to alternative locations or operators. Scale effects emerged gradually as successful mills expanded operations and achieved economies in raw material purchasing and power generation. Ultimately, these effects encouraged consolidation and development of larger, more efficient operations.

Cycle 2: Steam & Railway Age – Large-Scale System Coordination

The Steam & Railway Age represents humanity’s first technological cycle achieving systematic integration across vast geographical scales. George Stephenson’s 1829 Rainhill Trials demonstrated steam locomotion viability while establishing precedents for large-scale technological coordination. This cycle required deliberate coordination across multiple technical domains and geographical regions, exceeding organic clustering mechanisms of earlier periods.

Railway development integrated steam locomotive engineering, track construction, signaling systems, and operational coordination in unprecedented ways. Locomotive steam engines represented mechanical engineering achievements incorporating innovations in boiler design, valve systems, and mechanical transmission. Wrought iron rails provided foundations for efficient locomotive operation through precision manufacturing and installation techniques. Additionally, rail gauge standardization created interoperability enabling network effects and system optimization.

Complementary innovations extended beyond core mechanical systems to encompass communication, signaling, and operational technologies enabling safe network operation. Mechanical signaling systems provided communication capabilities for coordinating train movements safely across complex networks. Telegraph systems enabled real-time coordination across distances impossible with traditional communication methods. Furthermore, coupling systems and standardized freight designs created interoperability necessary for efficient goods transportation across different railway companies.

Infrastructure requirements drove innovations in civil engineering, construction, and project management that influenced infrastructure development for decades. Bridge engineering, tunnel construction, and route surveying required precision and scale pushing engineering capabilities to new limits. Station design and urban planning adapted to accommodate railway operations while exploiting commercial potential. Moreover, these physical infrastructure requirements demonstrated unprecedented coordination complexity.

Technical design standards achieved precision and coordination levels far exceeding earlier industrial systems. Rail gauge standardization enabled interoperability across thousands of miles constructed by different organizations. Locomotive specifications became increasingly standardized around boiler ratings, wheel configurations, and performance characteristics enabling predictable operation across different railways. These standards facilitated specialized manufacturing industries achieving economies while meeting diverse operational requirements.

Process standards in railway operations achieved unprecedented complexity through safety requirements and efficiency optimization. Timetabling systems represented revolutionary operational coordination approaches enabling simultaneous management of hundreds of trains across complex networks. Station procedures standardized passenger and freight handling for efficient network operation. Meanwhile, maintenance protocols ensured reliable system operation across equipment from different manufacturers.

Platform architecture standards represented the Railway Age’s most significant contribution through railway and telegraph system integration. This integration created the first truly integrated communication and transportation platform. Coordination capabilities would have been impossible with either system alone while creating additional emergent capabilities. Subsequently, these platform principles influenced all later technological development.

Network effects demonstrated unprecedented scale and complexity establishing patterns for subsequent technological development. Direct effects emerged through connectivity benefits increasing exponentially with network expansion. Each additional railway line increased transportation possibilities for existing lines, creating powerful expansion incentives. Indirect effects proved equally important through railway development stimulating complementary industries and services.

Economic cascade effects proved transformative for entire regions and industries. Railway success created demand for iron, steel, coal, and precision machinery while generating profits for reinvestment. These cascades drove industrial development across multiple sectors while creating employment and infrastructure supporting continued expansion. Furthermore, supply chain effects established foundations for modern industrial organization through reliable, scheduled transportation.

Cycle 3: Steel & Electrical Age – Dual-Platform Integration

The Steel & Electrical Age represents the first technological cycle achieving dual-platform integration combining material foundations with energy systems powering modern civilization. Andrew Carnegie’s 1875 Bessemer steel plant exemplifies convergence of metallurgical and electrical innovations creating technological foundations for urban development. This cycle demonstrated unprecedented sophistication in coordinating complementary technologies across multiple industries simultaneously.

Steel production innovations centered on Bessemer converter capabilities for removing impurities through controlled oxidation, producing consistent quality at industrial scales. Open-hearth furnaces provided complementary capabilities for specialized steel alloys with precise chemical compositions. These metallurgical advances required innovations in furnace design, temperature control, and chemical analysis enabling reliable production meeting specific requirements. Moreover, electrical systems provided precise control necessary for optimal steel production.

Electrical innovations integrated with steel production included sophisticated power generation and distribution systems providing consistent, controllable power for steel production while supporting broader applications. Direct current systems initially predominated, but alternating current eventually proved superior for long-distance transmission. These electrical systems became foundations for grid development while enabling precision manufacturing capabilities supporting increasingly complex mechanical systems.

Complementary innovations extended across construction, manufacturing, and transportation systems exploiting capabilities created by abundant steel and electrical power. Standard I-beam designs created modular construction systems enabling rapid, economical building construction. Electrical machinery enabled precision manufacturing capabilities supporting complex mechanical system production. Furthermore, steel construction and electrical power combinations enabled elevators, lighting, and systems making modern urban construction practical.

Steel grade specifications achieved precision levels enabling predictable performance across diverse applications. American Society for Testing and Materials protocols established systematic testing procedures ensuring steel quality and enabling performance-based specifications. Chemical composition standards for alloys enabled specialized steels optimized for particular applications. Additionally, process standards achieved unprecedented complexity through chemical analysis integration, temperature control, and timing coordination.

Platform architecture standards achieved unprecedented sophistication through steel construction integration with electrical power systems. This dual-platform integration created possibilities for industrial and urban development neither system could achieve independently. Steel-framed buildings could support electrical distribution while electrical power enabled precise control for steel production. Consequently, interoperability standards reached new complexity levels requiring integration with existing mechanical systems during transition periods.

Network effects fundamentally transformed urban and industrial development patterns through steel construction and electrical power combinations. Direct electrical network effects proved powerful as service became more valuable with expansion. Electrical lighting required minimum network size for cost effectiveness, but established networks could support diverse applications. Furthermore, indirect effects emerged through electrical appliance industries, contracting services, and engineering capabilities creating additional value.

Economic cascade effects created comprehensive transformation across manufacturing, construction, and service sectors. Steel production success enabled urban construction creating electrical system demand, enabling new manufacturing and commerce forms creating further demand for both capabilities. Manufacturing transformation through steel and electrical integration created effects across multiple industries while urban infrastructure transformation represented visible network effects.

Social cascade effects transformed urban nightlife and commercial activities while steel construction enabled commercial buildings housing new urban activities. Integrated utility system development represented crucial innovation in urban infrastructure coordination requiring careful coordination across electrical, gas, water, and transportation networks. These systematic approaches to utility integration established urban infrastructure models continuing to influence city planning today.

Cycle 4: Automobile Age – Comprehensive System Integration

The Automobile Age represents the first technological cycle achieving comprehensive integration across manufacturing, infrastructure, and service systems at continental scales. Henry Ford’s 1908 Model T introduction, combined with moving assembly line production, created innovation clusters transforming transportation, manufacturing methods, and social relationships throughout developed societies. This cycle demonstrated unprecedented sophistication in system orchestration and market creation.

Ford’s achievement extended beyond automotive engineering to encompass revolutionary manufacturing, distribution, and service system integration making automobile ownership accessible to mass markets. Internal combustion engines represented decades of development culmination in precision manufacturing, materials science, and fuel systems. However, engine potential could only be realized through integration with chassis design, transmission systems, and control mechanisms creating reliable, user-friendly vehicles.

Moving assembly lines represented revolutionary manufacturing approaches enabling dramatic cost reductions while maintaining quality standards. This innovation required systematic product, process, and workplace organization redesign optimizing efficiency and waste minimization. Assembly line success depended on precise materials flow coordination, worker training, and quality control systems representing major industrial organization advances. Additionally, complementary innovations extended across fuel production, distribution, and service systems creating infrastructure necessary for widespread adoption.

Financial innovations necessary for automobile adoption included consumer credit systems, dealer financing, and insurance products making ownership economically viable for middle-class consumers. These innovations represented crucial enablers transforming automobiles from luxury items to mass consumer products. Gasoline refining capabilities expanded dramatically meeting automotive fuel requirements while developing specialized products optimized for internal combustion engines. Meanwhile, service station networks provided fuel distribution and maintenance services enabling automobile operation across large geographical areas.

Technical design standards achieved unprecedented precision enabling interchangeable parts manufacturing across multiple facilities and suppliers. Society of Automotive Engineers specifications for bolts, threads, and components created industry-wide compatibility enabling supplier specialization and economies of scale. Fuel quality standards ensured reliable engine performance across different regions and conditions while octane rating systems enabled engine optimization for fuel characteristics. Furthermore, these standards created foundations for national gasoline distribution networks serving diverse automotive requirements reliably.

Process standards in manufacturing achieved unprecedented complexity through systematic production workflow analysis and optimization techniques. Moving assembly line sequencing required precise timing coordination across hundreds of workers and processes. Takt time calculations optimized production rates while maintaining quality standards, influencing manufacturing development across multiple industries. Product standards for components created foundations for specialized supplier industries achieving economies while meeting diverse manufacturer requirements.

Platform architecture standards emerged through automobile, road, and service system integration creating comprehensive transportation platforms. Automobile design accommodated road conditions and traffic patterns while road design optimized automobile performance and safety. Service systems needed to support diverse automobile designs while enabling efficient maintenance and repair operations. Consequently, interoperability standards achieved remarkable scope through supplier ecosystems producing compatible components for multiple manufacturers.

Network effects fundamentally transformed social and economic relationships throughout developed societies. Direct effects emerged through road networks becoming more valuable as automobile adoption increased. Each additional user increased economic justification for road improvements benefiting all users while creating positive feedback loops encouraging further adoption. Indirect effects proved transformative for entire economy sectors through tourism industries, retail adaptations, and housing development pattern shifts.

Infrastructure network effects created comprehensive transformation across transportation and communication systems. Road construction coordinated with bridge building, traffic control systems, and maintenance services creating integrated networks. These investments created employment opportunities and economic development reinforcing automobile adoption while creating additional network benefits. Moreover, service network effects emerged through dealer, repair, and parts supplier development creating comprehensive automobile ownership support systems.

Social cascade effects transformed residential patterns, family relationships, and leisure activities creating additional automobile transportation demand. Suburban living patterns enabled by automobile transportation created social expectations and lifestyle requirements reinforcing adoption. Social status associated with ownership created peer pressure effects accelerating adoption across middle-class populations. Additionally, these social transformations created network effects extending beyond economic considerations.

Path dependence effects created particularly durable influences continuing to affect urban development and transportation patterns more than a century later. Infrastructure lock-in emerged through road construction, parking facilities, and suburban development creating physical constraints on alternative transportation development. Switching costs associated with automobile-dependent systems proved extremely high due to integrated residential, commercial, and transportation system nature requiring coordinated replacement.

Cycle Five: Information Age – Sophisticated Ecosystem Orchestration

The Information Age represents the most sophisticated technological cycle achieved, demonstrating unprecedented capabilities for deliberate ecosystem orchestration and global coordination. Intel’s 1971 4004 microprocessor introduction, combined with networking protocol emergence, created innovation clusters characterized by modular design, platform thinking, and network-enabled coordination fundamentally transforming economic and social organization worldwide.

Microprocessors represented revolutionary computation approaches combining processing capabilities with programmability enabling unprecedented flexibility and scalability. Intel’s 4004 established principles that computing logic could be abstracted from specific applications and implemented through software programming. This abstraction enabled general-purpose computing system development adapting to diverse requirements without hardware redesign. Subsequently, platform architecture innovations integrated hardware capabilities with operating system software and development tools creating comprehensive programming environments.

Networking protocol development enabled distributed computing systems coordinating activities across global networks. Early protocols established packet switching, routing, and addressing principles enabling scalable network architectures. These protocols created foundations for internet development and global information system integration while complementary innovations extended across semiconductor manufacturing, software development, and telecommunications systems creating deployment infrastructure.

Hardware standards such as x86 instruction sets created platform consistency enabling software portability across different manufacturers and configurations. Interface standards including USB and Ethernet enabled peripheral and network connectivity supporting diverse system configurations. Software standards achieved remarkable complexity through programming language specifications, file format definitions, and application programming interface standards enabling modular development and integration.

Platform architecture standards represented the Information Age’s most significant contribution creating modular design and interface specification principles enabling ecosystem-wide coordination. Hardware abstraction layers separated application software from hardware specifics while network protocols enabled distributed system coordination. These architectural standards created foundations for continuous innovation within stable platform frameworks while interoperability standards achieved global scope through internet protocols, data exchange formats, and communication standards.

Network effects created unprecedented scale and complexity transforming economic and social organization globally. Direct effects emerged through communication networks becoming exponentially more valuable as user populations expanded. Platform effects proved particularly powerful through ecosystem development where application developers and users created mutually reinforcing value. Operating system platforms became more valuable as more applications were developed while applications became more viable as platform user bases expanded.

Data network effects emerged as information systems accumulated data enabling increasingly sophisticated services and capabilities. Search engines became more effective processing more queries while recommendation systems improved analyzing more user behavior. These effects created powerful competitive advantages becoming increasingly difficult to replicate as data accumulation continued. Furthermore, indirect effects proved transformative across virtually all economic sectors through e-commerce platforms, digital communication, and information system adoption.

Economic cascade effects extended across manufacturing, service delivery, and organizational coordination creating comprehensive economic transformation. Information system adoption enabled precision manufacturing through computerized control systems while service delivery benefited from automated customer service and transaction processing. These improvements created competitive advantages driving further adoption while social cascade effects transformed communication patterns, relationships, and cultural practices.

Advanced system architecture and ecosystem orchestration demonstrated unprecedented capabilities for deliberate ecosystem coordination enabling coordinated innovation across multiple organizations and domains. Platform strategy became sophisticated through ecosystem thinking considering complementary products, developer communities, and user adoption patterns simultaneously. Modular architectures enabled distributed innovation where different organizations could develop complementary components integrating seamlessly with platform architectures.

Global supply chain coordination achieved unprecedented sophistication through information system integration enabling real-time coordination across multiple continents and time zones. Manufacturing, distribution, and customer service systems coordinated through shared information systems optimizing efficiency while maintaining quality standards. These coordination capabilities enabled globalization patterns impossible without information system support while artificial intelligence and machine learning capabilities created system intelligence adapting and optimizing performance automatically.

Cross-Cycle Comparative Analysis and Evolution Patterns

Comparative analysis across all five cycles reveals consistent patterns in innovation cluster formation, maturation, and embedding within broader social and economic systems. Each cycle demonstrates increasing sophistication in standardization, coordination, and integration capabilities while creating more powerful network effects and path dependence mechanisms. The evolution from local mechanical coordination to global digital coordination represents fundamental transformation in technological system scale and sophistication.

Clustering formation processes exhibit distinct evolutionary patterns reflecting growing understanding of system orchestration principles. Early cycles emerged primarily through geographical proximity and resource availability with innovations converging organically around existing production centers. Later cycles demonstrate significantly more systematic approaches requiring deliberate coordination across multiple technical domains and geographical regions while contemporary cycles achieve comprehensive system integration across manufacturing, infrastructure, and service domains.

Codification sophistication demonstrates systematic advances in how informal knowledge becomes formalized into replicable systems supporting large-scale adoption and continuous improvement. Technical design standards evolved from simple dimensional specifications to comprehensive system architectures enabling ecosystem-wide coordination. Process standardization demonstrates systematic advances in operational knowledge codification and transferability across different contexts and organizations.

Network effects maturation demonstrates increasing sophistication in understanding and exploiting positive feedback mechanisms creating self-reinforcing adoption patterns and competitive advantages. Early cycles exhibited relatively simple direct network effects through physical connectivity and geographical proximity while later cycles demonstrate sophisticated indirect effects through complementary product and service development creating additional value reinforcing primary technology adoption.

Path dependence mechanisms evolved from primarily physical infrastructure constraints to encompass data, social relationships, and cognitive investments creating switching costs extending beyond economic considerations. Early cycles created relatively localized lock-in effects that could be overcome through new facility construction in alternative locations while later cycles created much more extensive effects requiring coordinated replacement across entire networks.

Temporal coordination evolution demonstrates dramatic advances in precision, scale, and automation enabling increasingly complex technological systems to operate reliably across vast geographical distances and diverse organizational contexts. Early systems relied on simple mechanical timing coordinating local operations while contemporary systems achieve microsecond precision across global networks enabling activities inconceivable in earlier eras.

Contemporary Applications and Future Implications

Understanding these evolutionary patterns provides crucial insights for navigating contemporary technological transformation challenges and opportunities. Organizations seeking successful innovation clusters can learn from identified patterns, particularly increasing importance of platform thinking, ecosystem orchestration, and network effect design for achieving transformative impact. Modern innovation clusters require deliberate coordination across multiple domains simultaneously with technical excellence becoming necessary but insufficient without complementary standardization development.

Strategic innovation planning must incorporate lessons about ecosystem orchestration, network effect exploitation, and standardization strategy development. Platform strategy development requires sophisticated understanding of network effects, standardization requirements, and ecosystem dynamics enabling value creation across multiple participant categories. Risk management approaches must account for increasing interdependence and complexity creating new systemic risks while enabling transformation opportunities.

Policy and governance framework evolution reveals fundamental changes in supporting technological development roles extending beyond traditional science and technology policy to encompass comprehensive economic development approaches. Regulatory framework development must anticipate increasing complexity and global scope while enabling innovation and competition within appropriate safety constraints. International coordination mechanisms must evolve addressing global scope and interdependence characteristics requiring unprecedented cooperation levels.

Future research priorities emerge from gaps and limitations identified through comprehensive analysis while considering evolving requirements for understanding contemporary and future technological development challenges. Emerging technology analysis represents crucial research applying developed frameworks to artificial intelligence, biotechnology, quantum computing, and other technologies potentially representing new cycles. Global coordination mechanism analysis investigates how sophisticated technological systems require international cooperation exceeding current institutional capabilities.

The ultimate implication demonstrates that humanity’s growing capability for sophisticated technological coordination and ecosystem orchestration represents fundamental advances in collective capacity for addressing complex challenges and creating beneficial outcomes. The evolution from emergent technological convergence to engineered ecosystem coordination represents transformation in human capabilities potentially enabling solutions to previously intractable challenges while creating new possibilities for human flourishing and social development.

These insights empower decision-makers to shape technological development trajectories maximizing societal benefits while minimizing associated risks and ensuring broad social participation in technological advancement. The frameworks developed provide foundations for future research while demonstrating systematic, comprehensive approaches’ importance for understanding technological change and implications for human society. Innovation clustering represents humanity’s most powerful tool for achieving rapid, beneficial technological transformation across multiple domains simultaneously, establishing fundamental mechanisms driving technological transformation throughout human history.

Strategic leaders must embrace these historical lessons to navigate increasingly complex technological environments successfully. Traditional linear approaches prove inadequate for managing ecosystem-level coordination requirements that characterize contemporary innovation challenges. Instead, organizations need dynamic frameworks adapting to rapid technological evolution while maintaining competitive positioning and stakeholder value creation.

Furthermore, timing considerations become increasingly critical as future technological cycles achieve global penetration more rapidly than contemporary information technologies. This acceleration creates opportunities for dramatic human capability improvements while presenting challenges for social adaptation and institutional development. Enhanced capabilities for managing technological transitions become essential for ensuring broad benefits from rapid change.

Moreover, understanding tipping point and cascade dynamics becomes crucial as technological systems exhibit increasing interconnection and interdependence. Small changes can trigger large-scale reorganization creating both beneficial transformation opportunities and systematic disruption risks affecting multiple domains simultaneously. Organizations must develop capabilities for identifying these dynamics early while positioning strategically for maximum advantage.

Additionally, ecosystem thinking emerges as fundamental for contemporary innovation success rather than component-level optimization focus. Competitive advantages increasingly arise from orchestration capabilities rather than individual technology superiority. Companies must coordinate complex relationships among technology providers, infrastructure developers, regulatory bodies, and user communities while creating platforms enabling distributed innovation.

We have previously discussed how and why Technology Cycle Five is stuck in an extended Turning point. The question is, do any of Cycle Five’s dynamics affect its remaining longer at the turning point?

Innovation Clustering During Extended Turning Points:

How Cycle Five’s Prolonged Crisis Affects Fundamental Innovation Dynamics

The question of whether innovation clustering—one of the most fundamental dynamics of technological development—is affected by our current extended Turning Point in Cycle Five reveals profound insights about the relationship between financial capital, institutional frameworks, and the basic mechanisms of technological convergence. Based on the comprehensive analysis of clustering patterns across all five technology cycles, the evidence suggests that while clustering as a fundamental dynamic persists during extended crises, its character, scale, and effectiveness are significantly altered in ways that may actually contribute to prolonging the Turning Point itself.

The Persistence of Clustering as a Fundamental Dynamic

Innovation clustering appears to be so fundamental to technological development that it continues operating even during extended periods of institutional and financial dysfunction. The basic mechanisms that drive clustering—complementary innovation convergence, knowledge spillovers, specialized labor concentration, and shared infrastructure development—represent core features of how human technological development occurs regardless of broader economic conditions.

During our current extended Turning Point (2000-present), we observe continued clustering activity across multiple domains. Silicon Valley’s evolution from semiconductor manufacturing to internet platforms to artificial intelligence demonstrates clustering’s persistence. The convergence of machine learning, cloud computing, big data analytics, and specialized hardware (GPUs, TPUs) around AI development shows classic clustering patterns continuing to operate. Similarly, biotechnology clustering around genomics, synthetic biology, and personalized medicine continues advancing despite broader institutional challenges.

However, the character of this clustering differs significantly from patterns observed during normal cycle progression. Current clustering exhibits several distinctive features that reflect the distorted institutional and financial environment of an extended Turning Point.

Distorted Clustering Characteristics During Extended Crisis

Financial Capital Misallocation Effects

The extended Turning Point’s most significant impact on clustering involves systematic misallocation of financial capital away from productive technological development toward speculative financial engineering. During normal Installation Periods, venture capital and growth capital flow toward genuine technological innovation and infrastructure development. However, during extended Turning Points, capital increasingly flows toward financial innovations, regulatory arbitrage, and asset price manipulation rather than fundamental technological advancement.

This misallocation manifests in several ways, affecting clustering dynamics. Venture capital increasingly favors business model innovations over technological breakthroughs, leading to clustering around platform monopolization rather than technological advancement. The emphasis shifts from developing new capabilities to capturing existing value through network effects and data accumulation. Consequently, clustering becomes oriented toward rent-seeking rather than value creation, reducing the transformative potential that characterizes healthy clustering during normal cycle progression.

Regulatory Capture and Innovation Suppression

Extended Turning Points create conditions where incumbent interests capture regulatory frameworks, systematically suppressing the creative destruction necessary for healthy clustering. Current regulatory environments often favor existing large platforms over emerging innovations, creating barriers to the kind of disruptive clustering that characterizes normal technological development.

This regulatory capture affects clustering by creating artificial barriers to entry and innovation diffusion. New clusters struggle to achieve critical mass when regulatory frameworks favor incumbents. The result is clustering that occurs within existing institutional constraints rather than driving institutional transformation. Innovation becomes incremental rather than revolutionary, clustering around existing paradigms rather than creating new ones.

Institutional Sclerosis and Coordination Failures

The extended nature of our current Turning Point reflects deeper institutional failures that directly impact clustering effectiveness. Normal Turning Points resolve relatively quickly (2-4 years historically – typically longer for the US) through institutional reform and regulatory realignment. Extended Turning Points indicate institutional systems’ inability to adapt to technological change, creating persistent coordination failures that affect clustering dynamics.

These coordination failures manifest in several ways. Public-private partnerships necessary for infrastructure development become dysfunctional due to political polarization and institutional capture. Educational institutions fail to adapt curricula to emerging technological requirements, creating skill mismatches that limit clustering effectiveness. International coordination mechanisms break down, fragmenting global innovation networks and reducing clustering scale and scope.

How Distorted Clustering Perpetuates the Extended Turning Point

The altered character of clustering during our extended Turning Point may actually contribute to prolonging the crisis rather than resolving it. Several mechanisms explain this self-reinforcing dynamic.

Reduced Transformative Potential

Healthy clustering during normal cycle progression creates genuinely transformative capabilities that drive broad economic and social change. Current clustering, constrained by financial misallocation and regulatory capture, produces innovations with limited transformative potential. Platform monopolization, data harvesting, and financial engineering create private value without generating the broad social benefits necessary for cycle resolution.

This reduced transformative potential means clustering fails to create the productivity gains and social benefits that historically enable Turning Point resolution. Instead of generating broad-based prosperity that enables institutional reform, current clustering concentrates benefits among narrow elites while creating social tensions that perpetuate institutional dysfunction.

Network Effects Concentration

Current clustering exhibits an unprecedented concentration of network effects within a small number of dominant platforms. Unlike historical clustering, which created competitive ecosystems with multiple participants, current clustering tends toward winner-take-all dynamics that concentrate power and wealth while reducing innovation incentives.

This concentration creates several problems for cycle resolution. Dominant platforms have incentives to suppress disruptive innovations that might threaten their positions. Innovation becomes oriented toward platform optimization rather than paradigm transformation. The result is clustering that reinforces existing power structures rather than creating new possibilities for economic and social organization.

Global Coordination Breakdown

Historical technology cycles achieved resolution through international coordination and institutional alignment. Current clustering occurs within increasingly fragmented global systems characterized by trade wars, technological nationalism, and institutional competition rather than cooperation.

This fragmentation reduces clustering effectiveness by limiting scale and scope. Global supply chains become weaponized rather than optimized for innovation. International talent flows face increasing restrictions. The result is clustering that operates below optimal scale while creating geopolitical tensions that further complicate institutional reform.

Conclusion

Innovation clustering as a fundamental dynamic persists during extended Turning Points, but its character becomes uniquely distorted in ways that may actually contribute to prolonging the crisis. Current clustering exhibits reduced transformative potential, excessive concentration of network effects, and fragmented global coordination that limits its capacity to drive the broad-based productivity gains and social benefits necessary for institutional reform and cycle resolution.

The fundamental nature of clustering as a driver of technological development means it will continue operating regardless of institutional conditions. However, the effectiveness of clustering for driving and expanding positive feedback loops that benefit social and economic transformation depends critically on the institutional frameworks within which it operates. Understanding this relationship provides essential insights for navigating our current technological and institutional challenges while working toward cycle resolution and the eventual Deployment Period that remains elusive more than two decades into the current Turning Point.

Next Chapter Seven: Socioeconomic Readiness

Below is the Clustering Innovations listing for the innovations and bibliographies for Disruptions Dawn within the technology cycle library.

Innovation and Bibliography listing Clustering Innovations

The main entrance to Technology Cycles Main Library – The Singularity Stacks Link

Link to return to Disruptions Dawn menu