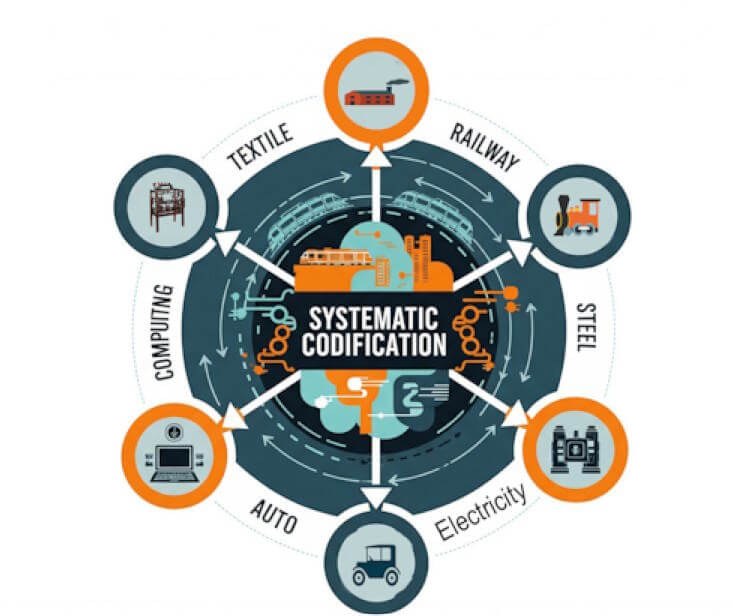

Codification as Liberation

The five major technology cycles reveal a fundamental pattern: systematic codification and standardization serve as the primary mechanisms enabling escape from turning point crises and transition to productive deployment periods. However, the fifth technology cycle—the digital revolution—has created a paradoxical form of codification that strengthens rather than liberates from lock-in, trapping the cycle in an extended turning point for over two decades.

Previous technology cycles demonstrated that codification serves a dual function: initially creating systematic coordination and competitive advantages during installation periods, but ultimately enabling market liberation during turning points by establishing open standards, knowledge transfer mechanisms, and competitive entry pathways. The turning point crisis forces the transformation of proprietary codification into public standards that enable broad economic participation and sustainable growth.

Arkwright’s emergent factory codification gave way to systematic mechanical standards that enabled competitive textile manufacturing. Stephenson’s systematic network codification evolved into open railway infrastructure standards that supported competitive operators. Carnegie’s scientific material codification established testing protocols and engineering standards that enabled alternative materials and construction methods. Ford’s comprehensive mechanical codification transformed into flexible manufacturing standards that supported diverse production approaches.

However, the fifth cycle’s ecosystem platform codification has created fundamentally different standardization patterns that strengthen rather than weaken monopolistic control. Digital platforms use proprietary algorithms, closed APIs, and data accumulation to create codification systems that become more exclusive and controlling over time rather than more open and accessible. This represents a qualitative departure from historical codification patterns and explains why traditional turning point resolution mechanisms have failed in the digital era.

Cycle One: From Proprietary Patents to Open Mechanical Standards

Initial Proprietary Codification and Crisis Formation

Arkwright’s textile revolution initially created highly proprietary codification through patent protection and trade secrets that concentrated industrial knowledge within a small number of factory operators. The water frame patents, protected until 1785, established legal monopolies over mechanical specifications while factory organization methods remained closely guarded industrial secrets. This proprietary codification enabled rapid initial development but ultimately created speculative bubbles and economic instability during the late 1780s.

The turning point crisis of 1793-1797 emerged partly from the limitations of proprietary codification systems that prevented broader economic participation in industrial development. Manufacturing knowledge remained concentrated among patent holders and their licensed operators, limiting competitive entry and creating artificial scarcity in industrial capacity. Speculative investment focused on acquiring patent rights rather than developing productive manufacturing capabilities.

Codification Transformation During the Turning Point

The turning point crisis forced systematic transformation of proprietary textile codification into more open and accessible standards that enabled competitive manufacturing and broader economic participation:

Patent Expiration and Legal Challenges: The expiration of key patents in 1785 and successful legal challenges throughout the 1790s transformed proprietary mechanical knowledge into public technical standards. Water frame specifications, spinning techniques, and factory organization methods became available for competitive replication and improvement. This conversion of private intellectual property into public technical knowledge enabled widespread manufacturing adoption.

Standardization of Mechanical Components: The crisis period forced systematic standardization of mechanical components, measurement systems, and manufacturing tolerances that enabled interchangeable parts production and competitive supplier development. Gear ratios, shaft dimensions, and power transmission systems achieved standard specifications that enabled modular factory construction and equipment replacement.

Skill Codification and Transfer: Manufacturing skills and operational knowledge were systematically codified through apprenticeship programs, technical manuals, and educational initiatives that enabled workforce development beyond the original factory locations. Mechanical skills, maintenance procedures, and quality control methods became transferable knowledge rather than proprietary trade secrets.

Regulatory Standards Development: Government inspection systems and quality standards established during the turning point created public oversight mechanisms that enabled competitive market participation while maintaining product quality and worker safety. These regulatory frameworks provided alternatives to private quality control systems while enabling market expansion.

Liberation Through Open Standards

The transformation from proprietary to open codification enabled systematic escape from the turning point through several mechanisms:

Competitive Market Entry: Open mechanical standards enabled new manufacturers to enter textile production without requiring patent licenses or trade secret access. Geographic expansion of manufacturing capability reduced regional monopolies while enabling specialization and efficiency improvements.

Innovation Acceleration: Public access to mechanical specifications enabled systematic improvement and innovation by multiple independent developers rather than relying solely on patent holders. Competitive development accelerated technical progress while reducing costs.

Economic Integration: Standardized manufacturing methods enabled systematic integration with broader economic systems including transportation, finance, and distribution networks. Open standards facilitated economic coordination while reducing transaction costs.

Cycle Two: From Network Monopolies to Infrastructure Standards

Initial Network Codification and Speculative Crisis

Stephenson’s railway revolution created systematic network codification through track gauge specifications, locomotive designs, and operational procedures that initially concentrated transportation coordination within integrated railway companies. The 4 feet 8½ inch track gauge, locomotive engineering standards, and timetabling systems created comprehensive coordination frameworks but remained largely proprietary to individual railway operators.

The Railway Mania of the 1840s created speculative investment in redundant and incompatible railway lines that lacked systematic technical coordination. Proprietary network standards prevented interoperability between competing systems while speculative financing focused on territorial control rather than systematic transportation service. The turning point crisis of 1848-1850 emerged from overcapacity, financial speculation, and operational inefficiencies created by incompatible proprietary systems.

Infrastructure Codification Transformation

The turning point crisis forced transformation of proprietary network codification into public infrastructure standards that enabled systematic coordination and competitive service provision:

Technical Standardization Mandates: The Railway Regulation Act of 1846 and subsequent legislation mandated systematic technical standards for track gauge, signaling systems, and safety procedures that enabled network interoperability. Private railway specifications were transformed into public technical standards that enabled competitive access and operational coordination.

Operational Procedure Codification: Timetabling systems, safety protocols, and maintenance procedures were systematically standardized through regulatory frameworks that enabled competitive operators to provide coordinated services. Private operational knowledge became public regulatory standards that ensured safety while enabling competition.

Infrastructure Sharing Protocols: The turning point period established systematic protocols for infrastructure sharing, terminal access, and through-service coordination that enabled competitive railway operators to provide integrated transportation services. Proprietary terminal and route control was transformed into regulated public infrastructure access.

Financial and Accounting Standards: Railway financial reporting and accounting standards were systematically codified to enable accurate investment assessment and prevent speculative manipulation. Private financial practices became public regulatory requirements that enabled sustainable investment and competitive market development.

Liberation Through Infrastructure Standards

The transformation from proprietary network control to public infrastructure standards enabled turning point escape through several mechanisms:

Competitive Service Provision: Standardized infrastructure enabled multiple operators to provide competitive transportation services while maintaining network coordination benefits. Technical interoperability enabled competition while preserving systematic coordination.

Investment Efficiency: Public infrastructure standards enabled accurate assessment of transportation investment productivity versus speculative asset appreciation. Systematic technical and financial standards enabled sustainable investment decision-making.

Economic Integration: Standardized transportation infrastructure enabled systematic economic integration across regions and industries. Open infrastructure access facilitated economic coordination while reducing transportation costs and enabling specialization.

Innovation and Improvement: Public technical standards enabled systematic innovation and improvement by multiple independent operators and equipment manufacturers. Competitive development accelerated technical progress while maintaining system coordination.

Cycle Three: From Industrial Secrets to Scientific Standards

Initial Scientific Codification and Industrial Speculation

Carnegie’s steel revolution created scientific codification through metallurgical chemistry, engineering calculations, and material testing procedures that initially remained proprietary to individual steel companies. Bessemer process specifications, heat treatment procedures, and alloy compositions were closely guarded industrial secrets that concentrated advanced steel production capabilities within a limited number of integrated companies.

The speculative boom of the 1880s created overcapacity investment in steel and electrical infrastructure based on proprietary technical claims that could not be independently verified. Industrial financing focused on acquiring technical secrets and patent control.

Scientific Standards Transformation

The turning point crisis forced transformation of proprietary industrial knowledge into public scientific standards that enabled systematic technical assessment and competitive development:

Material Testing Standardization: The crisis period established systematic material testing protocols through organizations like the American Society for Testing and Materials that transformed proprietary steel specifications into public technical standards. Tensile strength measurements, chemical analysis procedures, and performance testing became standardized scientific methods rather than proprietary industrial secrets.

Engineering Calculation Codification: Structural engineering calculations, load analysis methods, and safety factor determinations were systematically codified through professional engineering societies and educational institutions. Private engineering knowledge became public technical standards that enabled competitive design and construction.

Quality Control Procedures: Manufacturing quality control methods, inspection procedures, and performance verification systems were systematically standardized through regulatory frameworks and industry organizations. Proprietary quality systems became public standards that enabled competitive manufacturing while maintaining product reliability.

Technical Education and Certification: Engineering education curricula and professional certification requirements were systematically established to ensure competent technical practice across the industry. Private technical knowledge was transformed into public educational content that enabled workforce development and competitive capability.

Liberation Through Scientific Standards

The transformation from proprietary industrial knowledge to public scientific standards enabled turning point escape through several mechanisms:

Competitive Technical Development: Public scientific standards enabled new manufacturers to develop steel and electrical production capabilities without requiring access to proprietary technical secrets. Independent technical assessment enabled competitive entry while maintaining quality standards.

Innovation Acceleration: Systematic scientific methods enabled faster technical development and improvement by multiple independent researchers and manufacturers. Public technical standards accelerated innovation while enabling verification and improvement.

Investment Assessment: Scientific testing and measurement standards enabled accurate assessment of industrial investment productivity and technical claims. Systematic technical standards prevented speculative manipulation while enabling sustainable investment.

Economic Integration: Standardized materials and engineering methods enabled systematic integration with broader construction and manufacturing industries. Public technical standards facilitated economic coordination while reducing costs and enabling specialization.

Cycle Four: From Factory Secrets to Manufacturing Standards

Initial Manufacturing Codification and Speculative Crisis

Ford’s automotive revolution created comprehensive manufacturing codification through assembly line procedures, quality control methods, and worker training systems that initially remained proprietary to individual automotive companies. Time-and-motion studies, production scheduling methods, and supply chain coordination remained closely guarded competitive advantages that concentrated advanced manufacturing capabilities within integrated automotive corporations.

The speculative boom of the 1920s created investment based on claims about manufacturing productivity and market expansion that could not be independently verified. Financial speculation focused on stock price appreciation rather than systematic manufacturing capability development. The turning point crisis beginning in 1929 revealed fundamental disconnection between speculative valuation and productive manufacturing reality.

Manufacturing Standards Transformation

The extended turning point crisis (in the USA 1929-1943, in Europe 1929 to 1933) forced the transformation of proprietary manufacturing knowledge into public standards that enabled systematic productivity assessment and competitive development:

Scientific Management Systematization: The crisis period established systematic scientific management principles through government agencies and educational institutions that transformed private manufacturing knowledge into public productivity standards. Time-and-motion studies, efficiency measurement methods, and workflow optimization became standardized management tools rather than proprietary competitive advantages.

Quality Control Standardization: Manufacturing quality control procedures, statistical process control methods, and product testing standards were systematically codified through wartime production requirements and regulatory frameworks. Private quality systems became public manufacturing standards that enabled competitive production while maintaining product reliability.

Worker Training and Skill Standards: Industrial training methods, job classification systems, and skill certification procedures were systematically standardized through government programs and educational institutions. Proprietary worker training became public educational content that enabled workforce development across multiple manufacturers.

Supply Chain and Coordination Standards: Material specifications, component standards, and supplier coordination methods were systematically codified through wartime production requirements. Private supply chain knowledge became public procurement standards that enabled competitive manufacturing coordination.

Liberation Through Manufacturing Standards

The transformation from proprietary manufacturing knowledge to public standards enabled turning point escape through several mechanisms:

Competitive Manufacturing Entry: Public manufacturing standards enabled new companies to develop automotive and consumer goods production capabilities without requiring access to proprietary methods. Independent productivity assessment enabled competitive entry while maintaining quality and efficiency.

Innovation and Adaptation: Systematic manufacturing methods enabled faster adaptation and improvement by multiple independent manufacturers. Public manufacturing standards accelerated innovation while enabling verification and continuous improvement.

Investment Productivity: Manufacturing productivity standards enabled accurate assessment of industrial investment returns versus speculative asset appreciation. Systematic productivity measurement enabled sustainable investment decision-making.

Economic Integration: Standardized manufacturing methods enabled systematic integration with broader consumer economy and international trade. Public manufacturing standards facilitated economic coordination while enabling mass production benefits.

Cycle Five: The Codification Paradox – Why Platform Standards Strengthen Rather Than Liberate

Digital Platform Codification Characteristics

The fifth technology cycle has created ecosystem platform codification that operates through fundamentally different mechanisms than previous standardization patterns. Unlike historical cycles where codification ultimately enabled competitive entry and knowledge transfer, digital platform codification creates proprietary coordination systems that become more exclusive and controlling over time.

Proprietary Algorithmic Standards: Digital platforms operate through proprietary algorithms for search, recommendation, content distribution, and user interaction that remain completely opaque to external parties. Unlike mechanical specifications, chemical formulas, or manufacturing procedures that could be reverse-engineered or independently developed, algorithmic systems create black-box coordination mechanisms that prevent competitive replication or independent assessment.

Data Accumulation Dependencies: Platform codification requires massive data accumulation that creates competitive advantages unavailable through technical knowledge alone. Unlike previous cycles where technical specifications could be learned and applied independently, digital platforms require user data, behavioral patterns, and interaction histories that cannot be replicated without comparable user scale.

Network Effect Lock-in: Digital codification creates network effects that strengthen platform control rather than enabling competitive alternatives. Unlike infrastructure standards that enabled multiple operators, digital platforms become more valuable and exclusive as adoption increases, creating systematic barriers to competitive entry.

Ecosystem Integration Control: Platform codification operates through comprehensive ecosystem integration including APIs, development frameworks, and distribution channels that create dependencies rather than enabling independence. Unlike open technical standards, platform ecosystems require continued platform cooperation and can be withdrawn or modified unilaterally.

Why Traditional Codification Transformation Fails

The digital turning point has persisted because traditional mechanisms for transforming proprietary codification into open standards have proven inadequate for digital platform systems:

Technical Opacity and Complexity: Digital platform algorithms operate through machine learning and data processing methods that cannot be codified into transferable technical specifications. The complexity exceeds human comprehension and changes continuously through automated optimization, preventing the systematic technical codification that enabled previous cycle liberation.

Regulatory Incapacity: Government regulatory agencies lack the technical expertise and ongoing monitoring capabilities to transform proprietary platform algorithms into public standards. Unlike previous cycles where technical specifications could be mandated and verified, digital systems require continuous oversight far exceeding regulatory capabilities.

Global Scale and Jurisdictional Limitations: Digital platforms operate across national boundaries simultaneously, preventing the coordinated regulatory responses that successfully transformed proprietary standards in previous cycles. Platform operators can shift operations across jurisdictions to avoid standardization requirements.

Financial Integration and Systemic Risk: Digital platforms have achieved systematic importance to economic coordination that prevents the creative destruction necessary for standards transformation. Unlike previous cycles where competitive failure could force open standardization, digital platform failure would create systemic economic disruption.

The Summary of the Anti-Liberation Pattern of Digital Codification

Digital platform codification demonstrates systematic patterns that strengthen rather than weaken proprietary control over time:

Algorithmic Optimization Strengthening: Platform algorithms improve continuously through data accumulation and machine learning that increases rather than decreases competitive advantages. Unlike mechanical or scientific standards that could be mastered and replicated, algorithmic systems become more sophisticated and exclusive over time.

Ecosystem Dependency Deepening: Platform ecosystem integration creates increasing dependencies for developers, businesses, and users that strengthen rather than weaken platform control. Unlike open technical standards that enabled independent development, platform ecosystems create systematic switching costs that increase over time.

Data Value Compounding: Platform data accumulation creates competitive advantages that compound over time rather than depreciating like physical assets or becoming public like technical knowledge. User behavioral data, preference patterns, and social connections become more valuable with scale and time, preventing competitive replication.

Network Effect Reinforcement: Platform network effects create systematic advantages that increase with adoption rather than enabling competitive alternatives. Unlike infrastructure networks that could support multiple operators, digital platforms become more exclusive and controlling as they achieve larger user bases.

The Codification Requirements for Digital Turning Point Escape

Open Algorithmic Standards Development

Escaping the digital turning point will require transformation of proprietary algorithmic systems into open standards that enable competitive development and public oversight:

Algorithmic Transparency Requirements: Digital platforms must be required to publish algorithmic specifications, decision criteria, and optimization methods in forms that enable independent assessment and competitive replication. This would transform black-box proprietary systems into public technical standards similar to engineering specifications in previous cycles.

Data Portability and Interoperability Standards: User data, interaction histories, and preference profiles must become portable between competing platforms through standardized data formats and transfer protocols. This would enable competitive entry without requiring complete user base rebuilding, similar to infrastructure sharing in the railway cycle.

API Standardization and Access Requirements: Platform application programming interfaces must be standardized and made available to competitive alternatives and independent developers. This would prevent platform operators from withdrawing ecosystem access while enabling systematic competitive development.

Competitive Platform Infrastructure Development

Public Digital Infrastructure: Government investment in open-source alternatives to proprietary platform infrastructure could provide public digital coordination capabilities similar to highway systems that enabled automotive competition with railways. This would require systematic technical coordination and sustained public investment.

Decentralized System Standards: Blockchain protocols, peer-to-peer networking standards, and distributed computing frameworks could provide technical alternatives that operate independently of proprietary platform control. This would require systematic technical development and adoption coordination.

Interoperability Protocol Development: Technical standards for communication, data exchange, and service coordination between competing platforms could enable user choice while maintaining network coordination benefits. This would require unprecedented international technical cooperation.

Institutional Framework Innovation

Digital Platform Regulatory Agency: Specialized regulatory institutions with ongoing technical monitoring capabilities and international coordination authority could oversee platform standardization similar to railway regulation in the second cycle. This would require new institutional models combining technical expertise with democratic accountability.

International Digital Governance Framework: Comprehensive international agreements for digital platform standardization could prevent regulatory arbitrage while enabling coordinated competitive development. This would require unprecedented international institutional innovation.

Financial System Restructuring: Separation of speculative from productive digital investment through systematic assessment of platform productivity versus network effect manipulation. This would require fundamental reconsideration of digital asset valuation and investment regulation.

Conclusion: Codification as the Key to Digital Liberation

The historical analysis reveals that systematic codification transformation—from proprietary control to open standards—serves as the primary mechanism enabling turning point escape and transition to productive deployment periods. Each of the first four technology cycles demonstrated that crisis periods force the conversion of private technical knowledge into public standards that enable competitive entry, innovation acceleration, and broad economic participation.

However, the fifth technology cycle has created codification systems that resist this traditional transformation pattern. Digital platform codification operates through mechanisms—algorithmic opacity, data accumulation dependencies, network effect lock-in, and ecosystem integration control—that strengthen rather than weaken over time. This represents a fundamental departure from historical codification patterns and explains the persistence of the digital turning point.

The path to digital turning point escape requires systematic transformation of proprietary platform codification into open standards that enable competitive development and public oversight. This will require institutional innovations, technical developments, and international coordination comparable to the systematic reforms implemented during previous turning point resolutions.

Historic Stakes

The stakes of achieving proper digital codification transformation are historic. Success could enable a digital deployment period characterized by competitive innovation, broad economic participation, and sustainable productivity growth. Failure risks indefinite extension of the turning point with continued economic stagnation, social fragmentation, and democratic degradation.

The codification lens therefore provides essential insight for understanding both the persistence of the digital turning point and the requirements for eventual liberation. Just as previous cycles required transformation of proprietary industrial knowledge into open technical standards, the digital cycle will require systematic transformation of proprietary platform systems into public digital infrastructure that enables competitive development and democratic governance.

The historical precedents demonstrate that such transformations are possible when crisis conditions create sufficient pressure for systematic institutional and technical reform. The extended digital turning point may ultimately provide the crisis pressure necessary for achieving the codification transformation required for digital liberation and deployment period transition.

Next Chapter Four – Labor & Organization

Below is the Codification as Liberation listing for the innovations and bibliographies for Disruptions Dawn within the technology cycle library.

Innovation and Bibliography listing Codification as Liberation

The main entrance to Technology Cycles Main Library – The Singularity Stacks Link

Link to return to Disruptions Dawn menu